Combination of anaerobic and aerobic processes in treating textile wastewater has been used both in laboratory and industrial scale. Anaerobic process is applicable for degradation of textile dyes. Degrading dyes will reduce color to acceptable level in textile wastewater, also known as decolorization process. However, the resultant compounds of dyes breakdown could have toxic properties to environment. Therefore, further mineralization is needed by using aerobic process.

Nowadays, anaerobic process system generally uses simple technology, for example, fixed-bed bioreactor, UASB (upflow anaerobic sludge blanket), and baffled bioreactor. These bioreactors are limited in capability, especially in ability to increase anaerobic microbe concentration in the system. Therefore, the crucial method to enhance anaerobic bioreactor performance is increasing microbe concentration. Anaerobic membrane bioreactor (AnMBR) is introduced recently to treat wastewater anaerobically. The main advantage of this bioreactor is able to retain anaerobic microbes, thus increasing microbe concentration in the system. However, AnMBR application in treating industrial textile wastewater has not been widely reported in scientific journals.

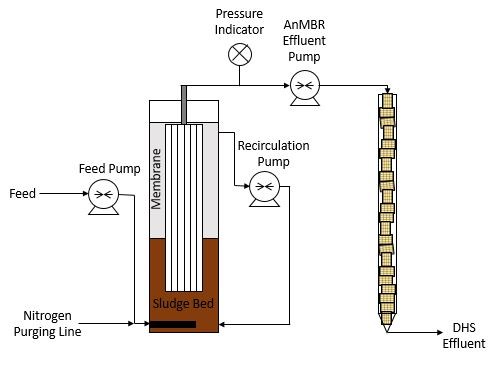

The objective of this research is to study AnMBR application to treat textile wastewater, then it is followed by aerobic biological process. Operating parameters in these experiments consist of HRT (Hydraulic Retention Time) and flux rate in the AnMBR. In aerobic process, DHS (Down Hanging Sponge) reactor was used. The experiments were maintained at defined HRT. This study was carried out in laboratory scale using synthetic wastewater. Each AnMBR was equipped with a hollow fiber PVDF membrane. Seed sludge was taken from textile wastewater treatment unit, then it was acclimatized in each reactor before running the experiments.

Contact Person:

Prof. Tjandra Setiadi (tjandra@che.itb.ac.id)