Pilot plants of MASARO Waste Industries in Cirebon and Cilegon have been constructed at the beginning of 2019 parallel with the grants by Dow Chemical International (USA) and PT Chandra Asri Petrochemical respectively. Trial operations for both units have been started from April 2019 by processing domestic waste of respective local communities to produce liquid fertilizer, animal feed, plantation media, fuel oil, and the recycled materials into zero waste. The goal regarding being zero waste has been successfully achieved, however, it needs further study especially in aspect of environmental safety and health.

Plastic refinery is one of the most essential units at MASARO Waste Industries that converts low-value plastic waste into fuel oil by using the produced heat from MASARO incinerator. The refineries produce ash as by-product for plant media, smoke (gas waste), and water as by-product (liquid waste). This study focuses on analysis of the produced wastewater and the released smoke to environment, and observes the onsite atmosphere. This analysis was carried out at Sucofindo, while the atmospheric condition was observed directly by monitoring smoke diffusion, smelt from waste treatment, noise from machinery, and other general effects.

The analysis results from Sucofindo are summarized as follows:

-

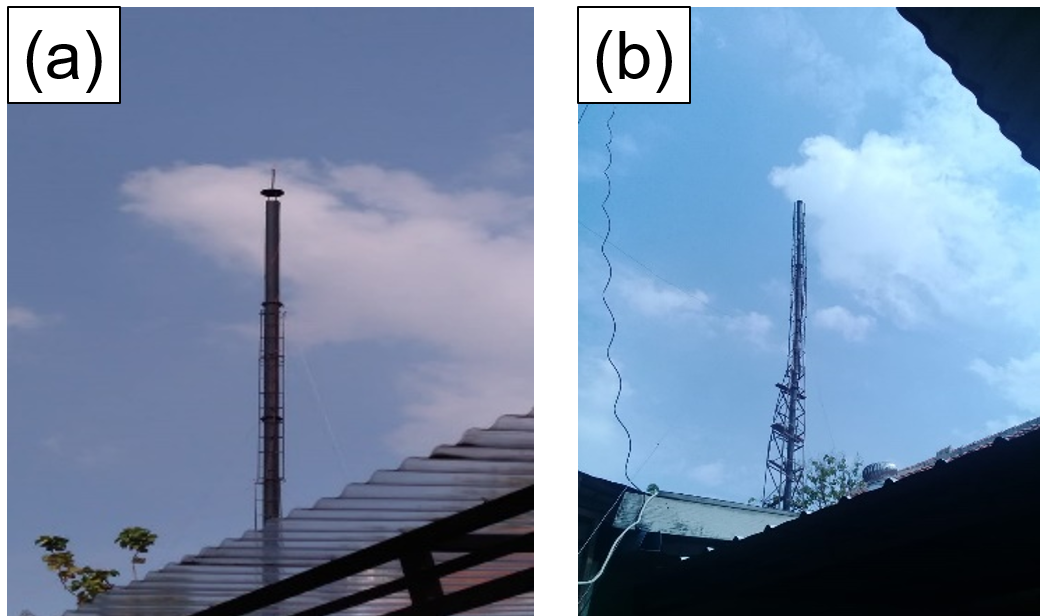

All aspects of the produced gas have met the environmental standard. However, chimney height needs to be 5 m higher.

-

All aspects of the wastewater have met the environmental standard, except nitrate, phenol, and COD by potassium dichromate. The wastewater needs to be treated afterwards.

According to the results and the atmospheric observation results, there are several recommendations for increasing the system.

-

The chimney needs to be 5 m higher than the existing one.

-

The wastewater needs to be treated further to meet the environmental standard.

-

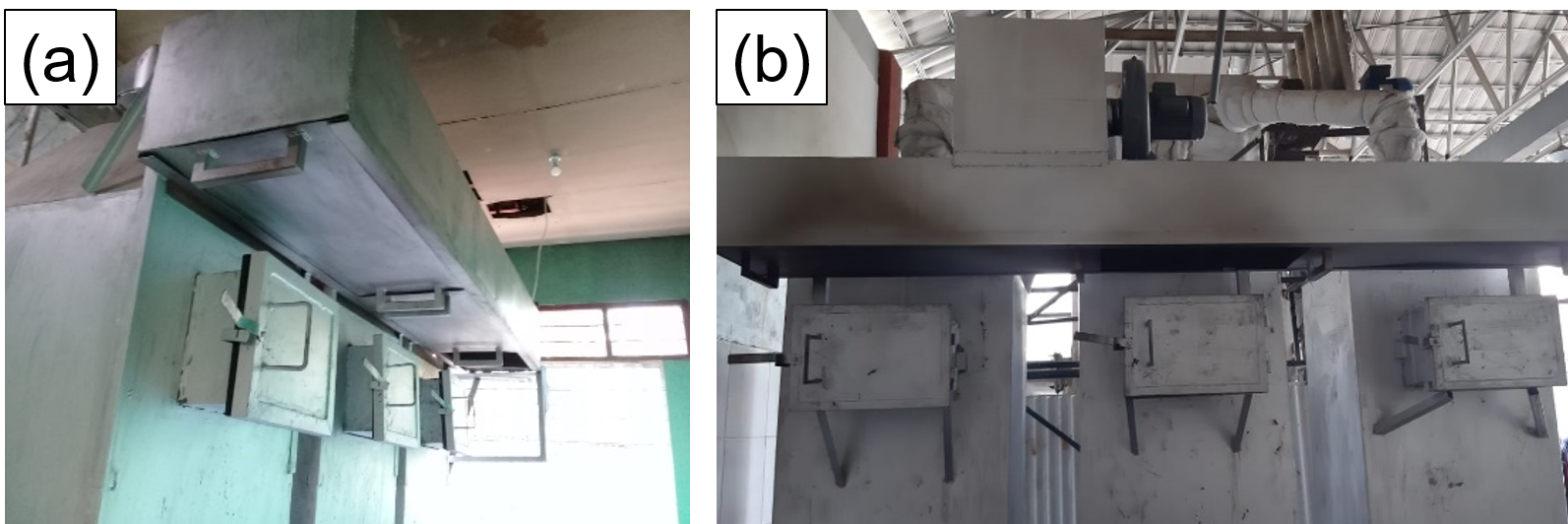

Incinerator feeder needs to be equipped with smoke suction to prevent smoke diffusion in the operating room.

-

Modification of the refinery units is required to improve heat transfer efficiency and increase the amount of heat supply.

The top three recommendations (1-3) have been implemented, however, the last recommendation (4) has been followed up by constructing a new design with compact form and enhancing the heat transfer.

Contact Person:

Akhmad Zainal Abidin, Ph.D. (zainal@che.itb.ac.id)