Coal fly ash is a solid waste from coal combustion in power generation. Utilization of fly ash and bottom ash has been limited to raw materials for concrete production or otherwise is dumped in landfill. Coal fly ash and bottom ash contains heavy metal, which causes pollution as well. In recent years, there have been some research regarding utilization of fly ash and bottom ash in synthesizing zeolite (alumino-silicate material). As coal fly ash contains silica and alumina, this could be a source of raw material for synthesizing zeolite (crystalline aluminosilicate), which has micropores in three dimensions while alumina and silicates are connected with oxygen atoms (Kongnoo et.al., 2017). This research aims to obtain methods and operating conditions for synthesizing zeolite from coal fly ash by using alkali fusion hydrothermal.

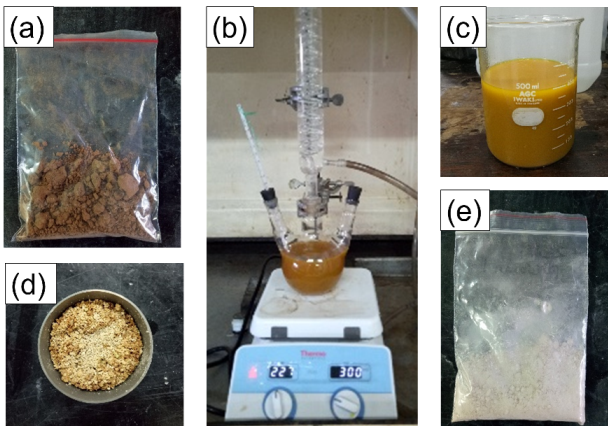

Coal fly ash was obtained from PT YTL Paiton, East Java. The synthesized zeolite was tested to remove copper ion in wastewater. A method to synthesize zeolite from the ash is alkali fusion hydrothermal. The ash was mixed with sodium hydroxide and the mixture was heated to specified fusion temperature for hydrothermal crystallization (Jha et.al., 2008). The first stage is pretreatment of the ash consisting of characterization using TGA and XRF, heating the ash to remove unwanted carbon, and adding hydrochloric acid to wash the ash. Secondly, zeolite is synthesized by three main steps, namely mixing with sodium hydroxide, fusion process, and mixing with sodium aluminate. The last stage is copper removal testing in wastewater.

Contact person:

Winny Wulandari, Ph.D. (winny@che.itb.ac.id)