Natural rubber-based products are widely used in daily life. There are three upstream-processed natural rubber products, namely crumb rubber, conventional rubber, and concentrated latex. Latex is easily damaged by clotting. In addition, concentrated latex contains 35-40 % w/w of water, therefore the packaging volume is relatively large and inefficient in transport. Latex also contains ammonia as an anti-clotting agent, thus the packaging must be specific, not leaky, and not cause unpleasant odor. This study aims to create a pilot plant of spray drying latex based on the simulation results, to test the performance, to evaluate the results of the performance test, as well as making improvement to rubber powder production to be well manageable.

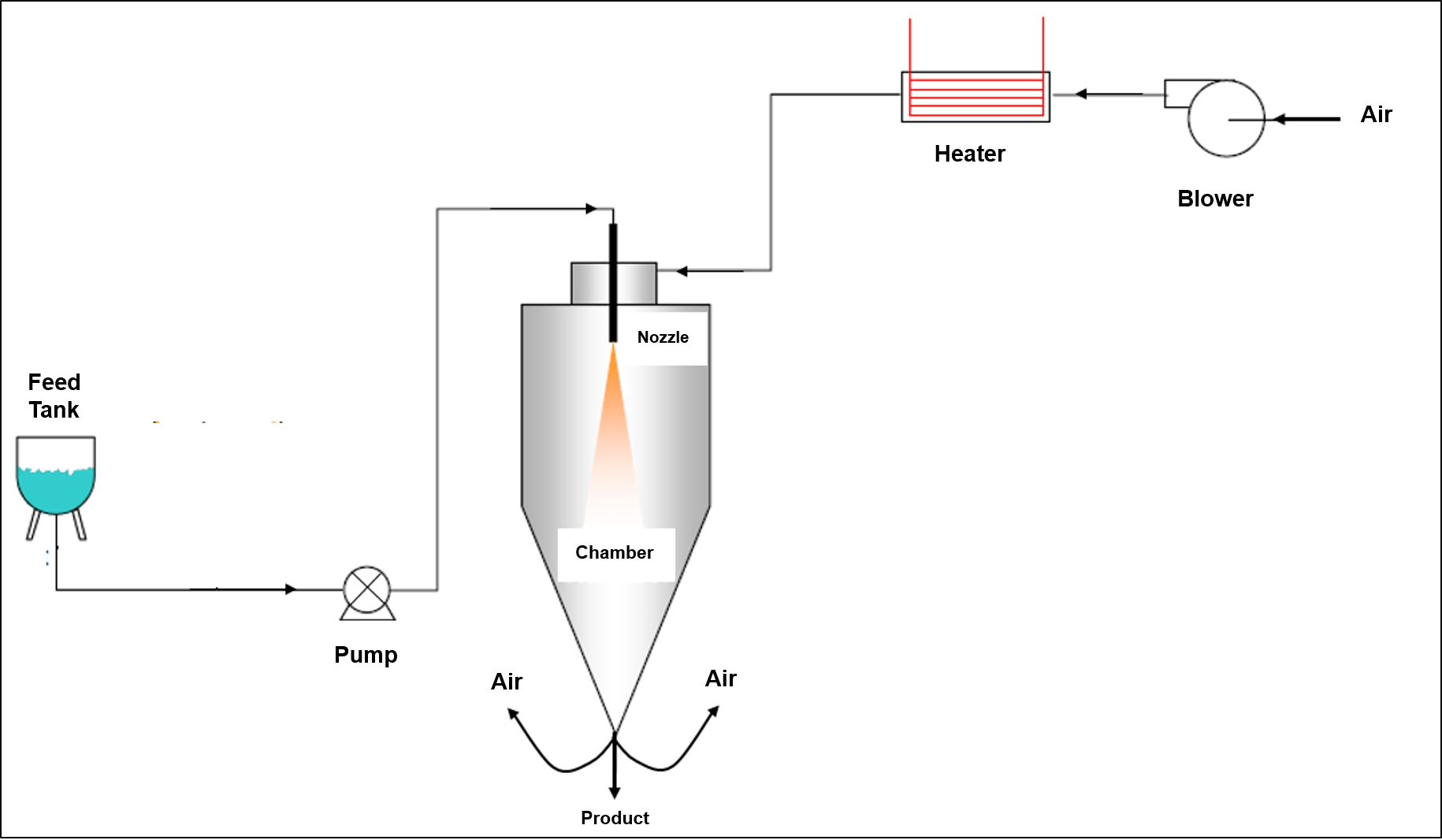

The research stages consist of data collection of spray dryer design, design verification, spray dryer construction, spray dryer test, and rubber powder characterization. Heating system used in the spray dryer was LPG gas-fired furnace. Water content characterization in spray-dried rubber powder used digital tool moisture meter and spectra of the products was analyzed by Fourier Transform Infrared Spectroscopy (FTIR).

Contact person:

Akhmad Zainal Abidin, Ph.D. (zainal@che.itb.ac.id)